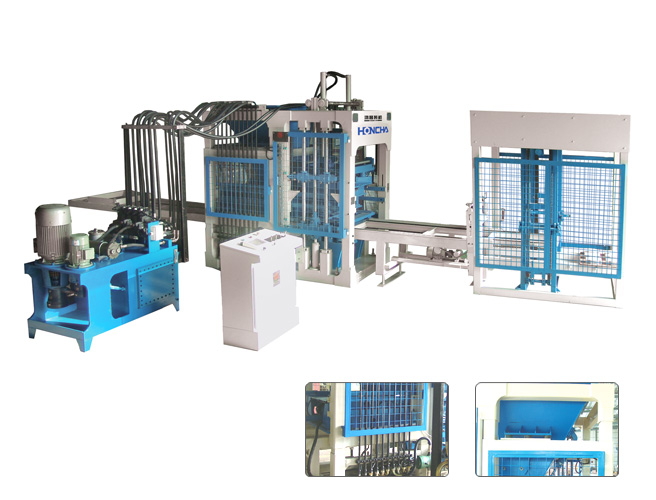

Application and Characteristics of QT6-15 Block Making Machine

(I) Application

The machine adopts hydraulic transmission, pressure vibration forming, vertical directional vibration of shaking table, so the shaking effect is good. It is suitable for small and medium-sized concrete block factories in urban and rural areas to produce all kinds of wall blocks, pavement blocks, floor blocks, grid wall blocks, chimney blocks, pavers, kerb stones, etc.

(2) Feature

1.The machine is hydraulic transmission, pressure vibration forming, can obtain very good products, after forming, the blocks can be stacked 4-6 layers for maintenance. And using double-layer material to produce color road bricks, forming cycle only takes 20-25 seconds. After moulding, it can leave the pallets for maintenance, which help the users save a lot investment in the pallets.

2.Hydraulic is mainly used to complete come down the mould, and rise the compaction head, feeding material, retreating material, come down the compaction head, raise the pressure, lifting the mould, then the product extrusion. Mechanical assistant, pallet conveyor and block conveyor can cooperate with each other to shorten the forming cycle time.

3.The intelligent control of PLC (industrial computer) is used to realize man-machine dialogue. It is an advanced production line which integrates machinery, electricity and liquid.